07

2024

-

08

Industry New Knowledge... "Journal of Dentistry" an in vitro study on the accuracy of 3D printing mixed resin-ceramic crown, veneer and high-inlay concave surface.

Author:

Recently, Alexey Unkovskiy team published a study entitled Accuracy of the intaglio surface of 3D-printed hybrid resin-ceramic crowns, veneers and table-tops: An in vitro study in "Journal of Dentistry" to study the effect of construction angle on the accuracy (authenticity and precision) of 3D printed crowns, high inlays and veneers.

Original link: https://www.sciencedirect.com/science/article/pii/S0300571224001301

If it cannot be opened, please copy the URL to the browser.

In the past few years, additive manufacturing (AM) has seen tremendous growth in the medical field and has continuously gained importance in the dental field. In the field of dentistry, 3D printing is used to manufacture various movable instruments, such as splints, surgical guides and denture bases. But there is little information about the accuracy of permanent repair of AM. In the thematic literature on this topic, only 4 studies were found, which only examined the accuracy of crowns, missing any data on more complex objects (such as veneers and onlays). Dimensional accuracy should be considered an important aspect of clinical success because it may affect the internal and marginal fit of the prosthesis. Dimensional accuracy should be considered an important aspect of clinical success because it may affect the internal and marginal fit of the prosthesis. The construction angle in the 3D printing molding process is an important aspect, which will affect the accuracy of various objects in the dental field.

Study setup: Hybrid resin-ceramic crowns, onlays, and veneers printed using DLP at 0 °, 30 °, 45 °, 60 °, and 90 ° build angles

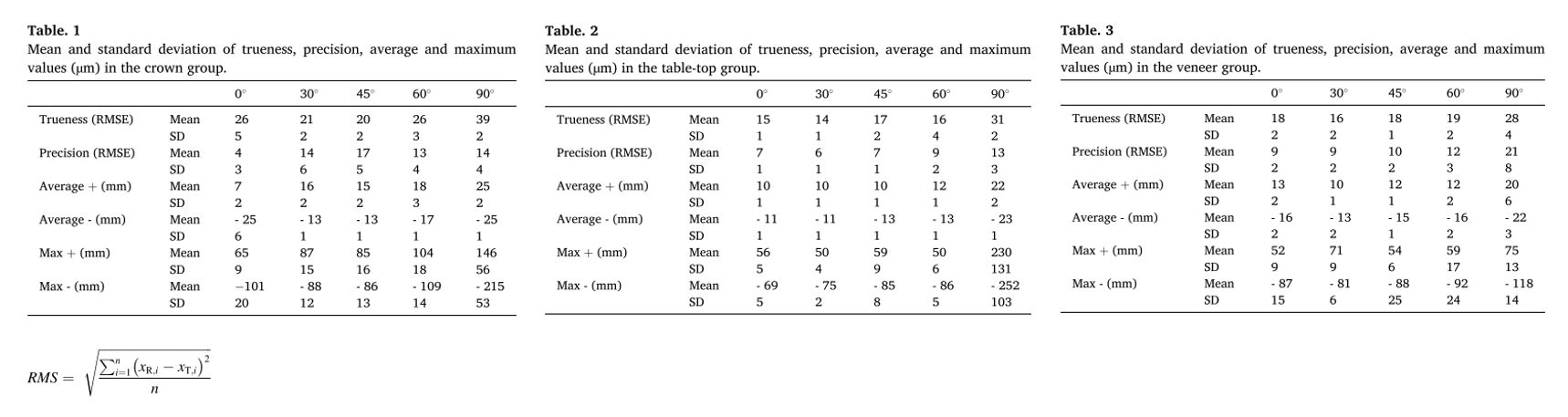

△ is the average and standard deviation of accuracy, precision, average and maximum (µm) in the crown group, high inlay group and veneer group, respectively.

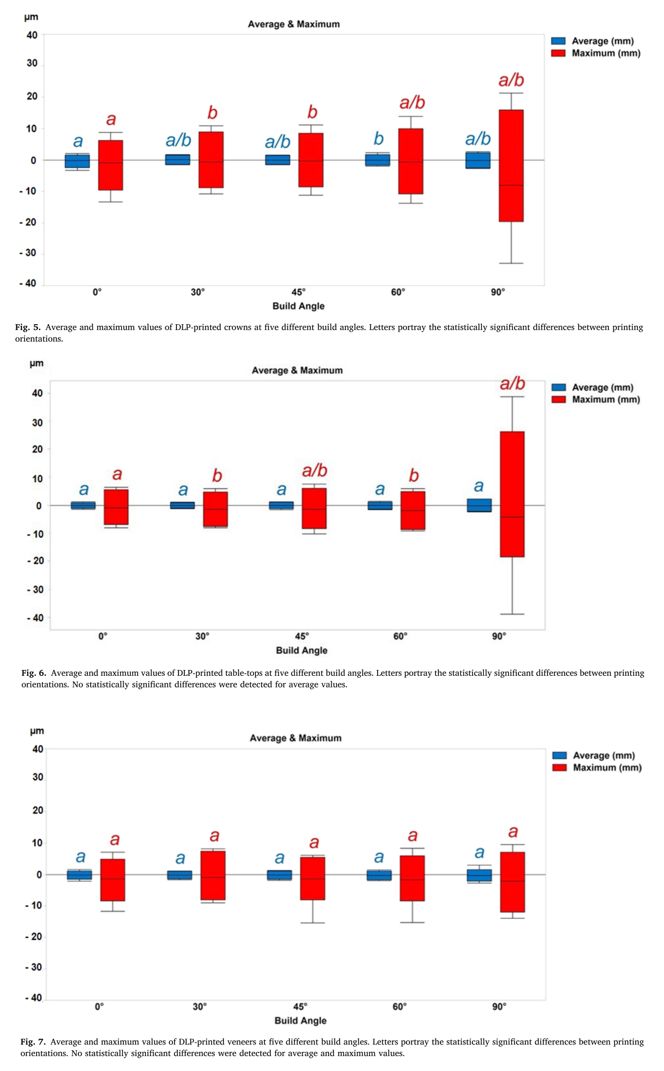

△ Accuracy at five different construction angles. Letters describe statistically significant differences between print directions.

Average and maximum values of delta DLP printed veneers at five different build angles. The letters describe statistically significant differences between the print directions.

Color map showing the authenticity of each restoration type: crown, onlay and veneer according to the construction angle. The minimum and maximum ranges are set to ± 0.2mm and the tolerance is set to ± 0.005mm. Positive values (yellow-red) indicate a convex shape and negative values indicate a concave shape.

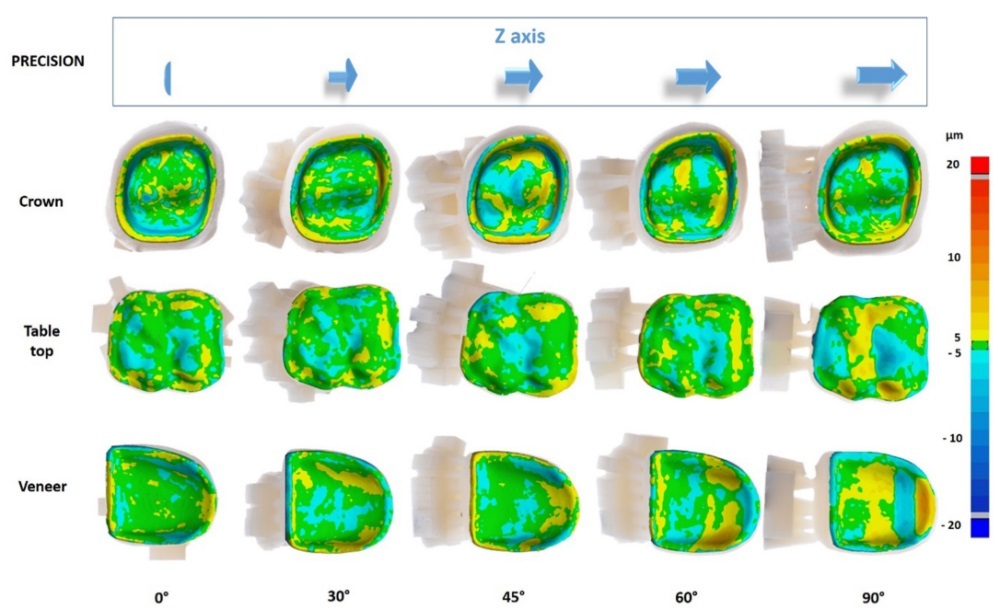

The color map shows the accuracy of each restoration type: crown, onlay and veneer according to the construction angle. The minimum and maximum ranges are set to ± 0.2mm and the tolerance is set to ± 0.005mm. Positive values (yellow-red) indicate convexity and negative values indicate concavity.

Conclusions: Within the limitations of this study, the following conclusions can be drawn. As for authenticity, 30 degrees seems to be the best construction angle for crowns and onlays. For veneers, the angle of fabrication of all restorations is acceptable except for 90-degree restorations. At a restoration angle of 90 degrees, the authenticity and accuracy of all restoration types are the lowest. When the crown is printed at 0 degrees, most of the interference with the mold may occur on the recessed occlusal surface. As for the accuracy, 30 degrees and 45 degrees seem to be the best angles for crown and onlay construction. When increasing the construction angle, the area of greatest possible interference moves to the wall of the crown.

△ The above picture shows the zirconia crown and veneer printed by Adventure Technology using DLP ceramic 3D printing equipment independently developed.

Related News

undefined

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible, thank you!