11

2024

-

09

Industry New Knowledge... "Journal of Manufacturing Processes" through digital light processing 3D printing glass aspheric lens.

Author:

Industry new knowledge

Recently, a team led by Yaguo Li from the Precision Optical Engineering Research Center published a research entitled 3D printing of glass aspheric lens by digital light processing in "Journal of Manufacturing Processes". Centimeter glass aspheric lenses were 3D printed through digital light processing (DLP) technology, using ultraviolet curing resin and silica nanoparticle slurry. Spin coating post treatment reduces laminar structure.

Original link: www.elsevier.com/locate/manpro

Adventure Technology official website: http://www.adventuretech.cn/

If it cannot be opened, please copy the URL to the browser.

research content

Fused silica glass is widely used because of its excellent optical properties and heat and chemical resistance, but its high brittleness and low fracture toughness make it difficult to process. Traditional methods such as grinding and polishing have low efficiency and high cost. Precision glass molding (PGM) and chemical etching have the problems of low material removal rate and high processing cost. 3D printing technologies such as FDM, TPP, STL and DLP offer the flexibility and high resolution to fabricate complex glass structures, but have limitations such as slow printing speed and obvious layered structure. Although there are improved methods to reduce layered structures, 3D printing centimeter-scale glass optics still faces challenges.

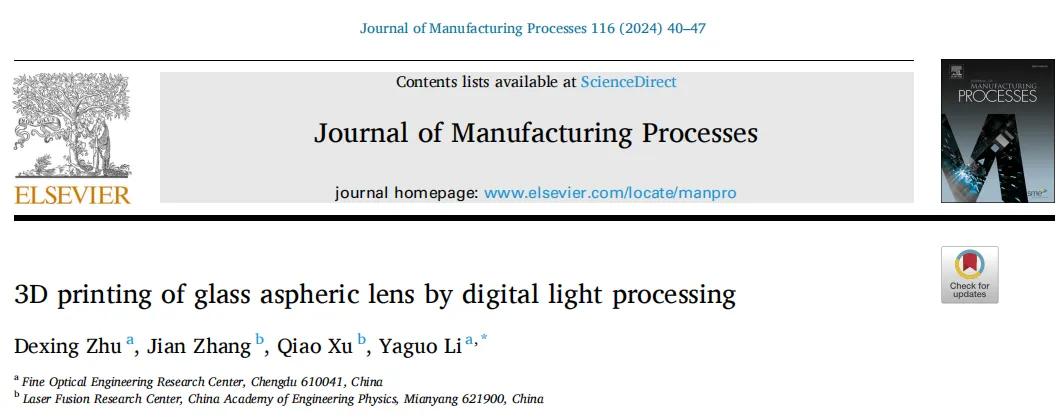

This study proposes a method of 3D printing glass aspheric lenses that combines DLP and post-curing processes. A glass paste consisting of organic resin and silica nanoparticles was used for printing, and the layered structure was reduced by spin coating and post-curing. Finally, degreasing and sintering are achieved by heating treatment to produce a glass lens. The optical performance and manufacturing precision of the printed lens were evaluated experimentally.

1,(a) 3D printing process of a glass aspheric lens. A glass slurry consisting of silica nanoparticles and a UV-curable monomer premix was homogenized for use as a 3D printing material for a DLP printer. In order to reduce the lamellar structure, the printed lens was subjected to a post-curing step after its surface was spin-coated with the unpolymerized slurry. Subsequently, the polymeric samples were converted to glass by a thermal debanding and sintering process. (B) The designed aspheric lens is optimized with a wavelength of 532 nm, a focal length of 168mm, and a radius of 10.5mm. Based on the designed lens, an STL format model is established, which is enlarged to compensate for the shrinkage caused by delamination and sintering.

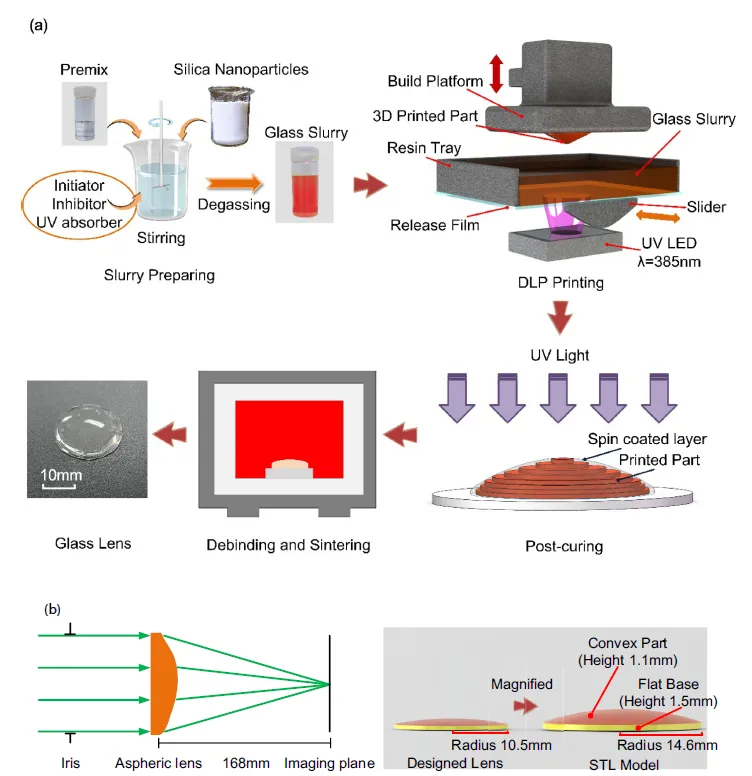

Figure 2, SEM micrograph of Aerosil OX50.

△ Fig. 3, the viscosity of the premix and the glass paste is measured by a parallel plate rheometer, and the gaps between the parallel plates are 10 μm, 20 μm, 50 μm and 1mm, respectively. The premix exhibits almost Newtonian fluid properties at the solid-liquid interface, and the viscosity is basically the same at different gaps. At 10 μm and 20 μm gaps, the viscosity fluctuates significantly with increasing shear rate.

4, the delaminated, sintered printed sample and its microstructure.

Delta Figure 5, sintered samples printed with glass pastes with different solid loadings, the shrinkage decreases as the solid loading increases.

6,XRD results show that there are no obvious narrow peaks and peaks, indicating that there is no crystallization during the sintering process.

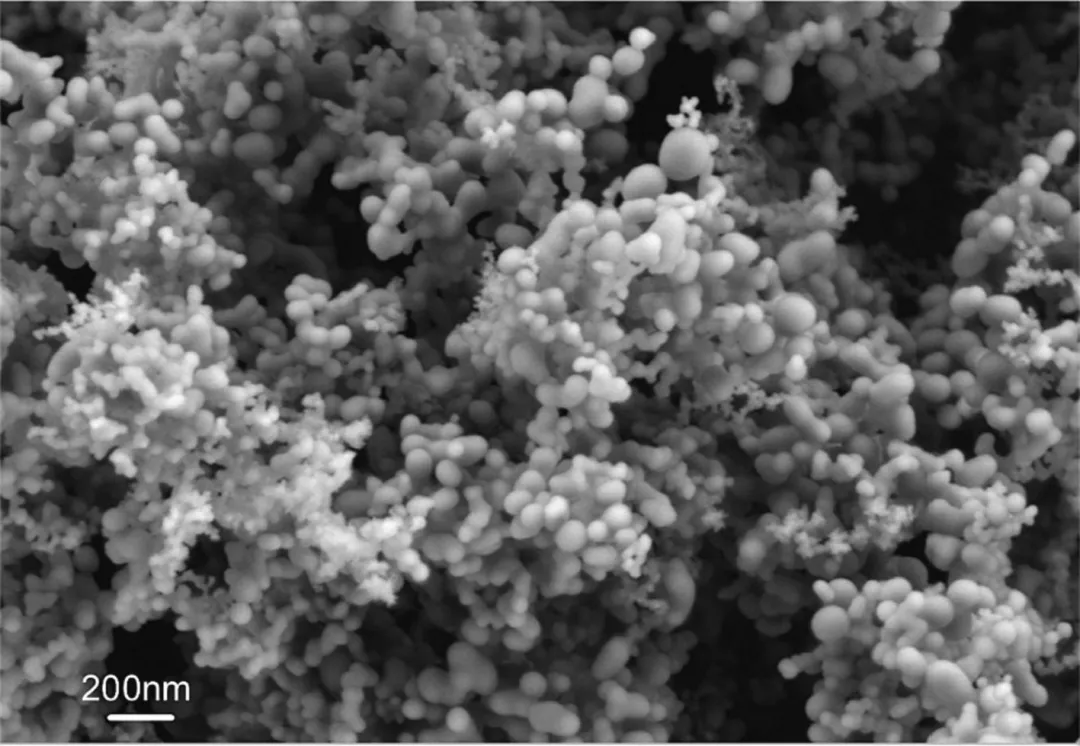

△ Figure 7,(a) The surface roughness of 2 areas on the measured printing lens is 14 nm and 15 nm respectively. (B) shows the surface profile of the printed lens, compared with the designed curve. The maximum deviation of the printed surface was 170 μm.

8,(a) Experimental setup for resolution testing. (B) The imaging resolution of the target image display of the reference lens (groups 4-5) is 90.5lp/mm. (c) The imaging resolution of the target image (groups 4-5) of the printing lens was 45.3lp/mm.

research conclusion

This article introduces a method for 3D printing centimeter-level aspheric glass lenses through DLP using nanoparticles and organic resin glass paste. Through the post-curing process to reduce the layered structure, degreasing and sintering to achieve transparent glass components. The rheological properties of the glass paste optimized the printing parameters to obtain a smooth surface (RMS < 15 nm), but the imaging resolution was limited to 45.3 lp/mm. The results show that DLP combined with post-curing can produce glass lenses with high transmittance and low surface roughness, and the manufacturing accuracy needs to be improved.

Consult Now

If you are interested in our products, please leave your email and we will contact you as soon as possible, thank you!